FIRST LEVEL OF MODERNIZATION

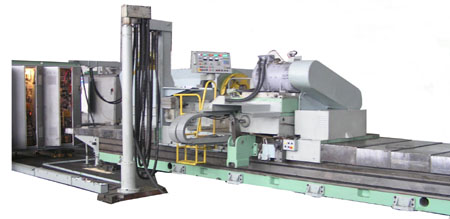

SCOPE OF WORKS ON CAPITAL REPAIR AND MODERNIZATION OF 3415K (3417V, 3415E) ROLL-GRINDING MACHINE

Kharkiv Machine-Tool Building Plant, PJSC, has already done capital repair and modernization of nine roll-grinding machines of 3415E and 3417V types:

Scope of works for each machine

1. The machine will be equipped with CNC system on the base of logical control pedestal manufactured by KONSTAR, Ukraine or SIEMENS, Germany:

- Number of controlled coordinate axis: 2 - cross-sectional axis of grinding wheel head shift – “X” axis

- Finish machining of roll in automated mode according to the CNC program.

- Diagnostics for all machine system units

- Free programming of machining cycle, etc.

- longitudinal axis of bogie shift – “Z” axis

Bulky electric cabinet with equipment and showing devices, set on the bogie of each machine, will be replaced by terminal cabinet with handy turning main machine control panel, mounted on it, with necessary operating controls (buttons, switchers, grind and supply speed sensors, warning lamps and showing devices).

2. The machine will be equipped with device with hand-driven and automated control system for balancing of grinding circle on the machine directly (it shall be mounted to disk chuck for mounting of grinding circle) and electronic measuring device for evaluation of balancing quality.

2. The machine will be equipped with device with hand-driven and automated control system for balancing of grinding circle on the machine directly (it shall be mounted to disk chuck for mounting of grinding circle) and electronic measuring device for evaluation of balancing quality.

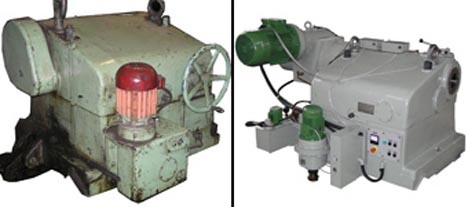

3. Bogie shift gearbox will be replaced for new one with modernized design and drive from AC/DC electric motor. At the same time speed of bogie quick shift will be increased up to 6000 mm/min (instead of 2500 mm/min before modernization). Shall be provided widened range of variable speed of longitudinal supply: 25...60000 mm/min (instead of 100…2500 mm/min before modernization).

3. Bogie shift gearbox will be replaced for new one with modernized design and drive from AC/DC electric motor. At the same time speed of bogie quick shift will be increased up to 6000 mm/min (instead of 2500 mm/min before modernization). Shall be provided widened range of variable speed of longitudinal supply: 25...60000 mm/min (instead of 100…2500 mm/min before modernization).

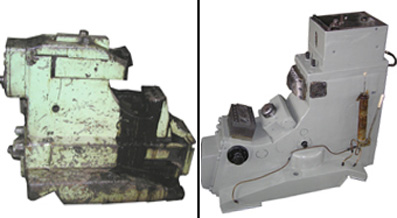

4. The mechanism of cross supply of grinding circle will be replaced with new one of modernized design. The mechanism will provide execution possibility of unbroken stageless-variable supplies of grinding circle with the aim to provide compensation of its runout while rough grinding as well as while periodical supplies (while bogie reverse). Drive of unbroken supplies shall be provided with AC/DC electric motor.

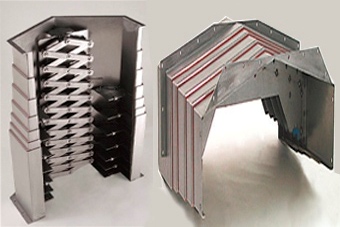

5. The guiding bars and oil tank along the whole housing width from two sides of bogie will be guarded with telescopic protection of modern design manufactured by European companies: : “Hestego”, Czech Republic, or “KabelSchlepp”, Germany.

5. The guiding bars and oil tank along the whole housing width from two sides of bogie will be guarded with telescopic protection of modern design manufactured by European companies: : “Hestego”, Czech Republic, or “KabelSchlepp”, Germany.

6. Each machine will be supplied with device (mounted on the back head) for truing of grinding circle by hard-alloyed roller and 8 hard-alloyed rollers.

7. Each machine will be equipped with hydraulic jack for preliminary loading of rolls and support backrests protection from damage during rolls loading by travelling crane. Set of hydraulic jacks will be equipped with hydraulic station and hydraulic apparatus.

8.System of supply and purification of cutting fluid will be changed in every machine. Instead of supply of cutting fluid from open basin, situated along bogie housing, by pump, set on bogie staircase, the supply will be made with the help of rubber tubes through electric supply column of bogie units. Reservoir along housing will be shut. Purification of cutting fluid with the help of clarifying tank (planned size: 2000x1800 mm), mounted lower than housing level and system of supply and purification of cutting fluid (planned size: 3000x1800 mm). Constant slime wash-out will be foreseen in housing pan with separate flow of cutting fluid.

9. Electric equipment of machine will be changed for new, modern equipment manufactured by leading domestic and foreign companies:

9. Electric equipment of machine will be changed for new, modern equipment manufactured by leading domestic and foreign companies:

- AC/DC electric motors completed with drives of domestic and foreign manufacturers (Siemens, Germany)

- electric cabinets of one-side service with compulsive cooling and protective degree of IP54

- “Konstar” programmable logic controller, which provides control of values and speed of shift of machine executive units, diagnostics of the main systems, etc.

10. “Tailstock” unit. Instead of hand ship of pintle with thrust center, tailstock will be equipped with device for electro-mechanical shift of pintle with electric motor drive. Tailstock will be equipped with new hard and additionally turning thrust center with angle of operating cone of 75º. Tailstock will be equipped with centralized compulsive lubricating system for pintle and longitudinal guide bars.

11.Every machine will be supplied with two new lunettes. One of two lunettes will be equipped with electric drive of thin supplies of upper insert (of DC electric motor) to provide possibility to control cone degree of machined part from work place on machine bogie.

Scope of capital repair of machine units

In the process of capital repair all units and parts will be tested for defects and repaired; in case of necessity pluck-out items will be replaced by new ones.

Machine testing at the Kharverst

After capital repair and modernization each machine will be set on testing bench at the Kharverst plant. The machine will be checked on its geometrical accuracy in accordance with “Act of machine acceptance”; on the next step the machine will be tested on no-load operation and under load and only after it the machine will be supplied to the Customer.

.png)